MOOG®

HEAVY DUTY

U-JOINTS

Premium driveline components from MOOG®, the preferred brand of replacement chassis parts by professional technicians

Heavy duty performance and durability

Built strong and durable to meet the needs of fleets, off highway, and commercial vehicles

MOOG® Heavy Duty u-joints’ radial lubrication grooves and anti-drainback feature provide optimal lubrication flow. Their exclusive thrust washer design absorbs axial loads, preventing metal-to-metal contact.

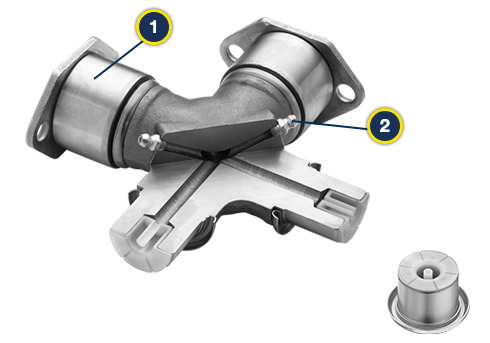

1. Case-hardened bearing cup

Bearing cups are cold-formed and case-hardened with a state-of-the-art manufacturing process to ensure the highest quality. All parts are ground to stringent tolerances with quality control inspections at every step of the manufacturing process

2. Greaseable design

Grease fitting holes are drilled and tapped. Most MOOG® Heavy Duty u-joints feature dual grease fittings for easier access during regular joint maintenance

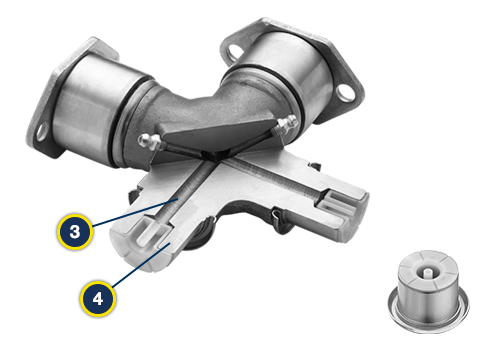

3. Grease reservoirs

Cross trunnions have large grease reservoirs that feature radial grease channels for optimal grease distribution

4. Cross trunnions

Cross trunnions are ground during manufacturing to a 15-25 RMS finish. This provides a smooth surface, free of microscopic grooves that can cause premature wear

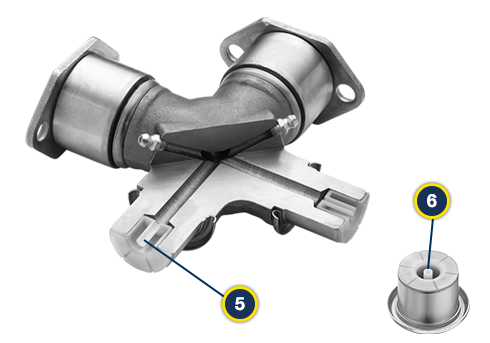

5. Anti-drainback valve

An internal anti-drainback valve is integrated into the thrust washer to control lubrication flow and prevent dry start-up

6. Patented thrust washer

The patented thrust washer incorporates an anti-drainback feature found on medium duty, heavy duty, off-highway and truck PTO joints

Quick-Look Benefits

Innovative

Incorporate numerous features for maximizing life, preventing failure

Durable

Forged and heat-treated

Safer

Meet or exceed OE standards

Easier

Engineered for aftermarket service environment