DID YOU KNOW: Advice for the professional

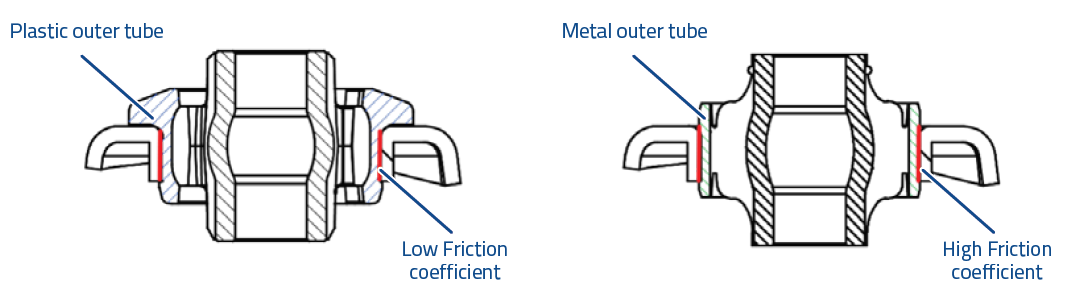

The friction coefficient between steel (the arm body material) and plastic (the bush outer tube material) is very poor. This is why MOOG has replaced the plastic bush with one of a metal design.

Whilst the plastic bushes remain secure under normal driving conditions, a high impact (such as a kerb, pothole, or raised surface, especially at a roundabout) can generate the force required to cause the plastic bush to pop out from its arm body bore.

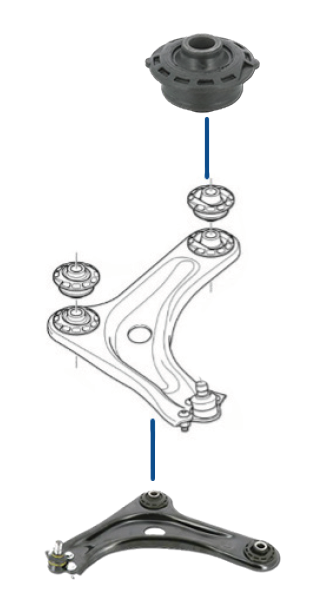

OVERVIEW

Early models of the Citroën C2 and C3 were equipped with wishbone arms fitted with plastic-tube bushes :

APPLICATIONS:

- CITROEN C2 - C3 2003 --> 2009

- PEUGEOT 1007 2005-->

PLASTIC TO METAL BUSH

MOOG Engineers have consistently sought to improve the pull-out force of its plastic bushes and have achieved performance which exceeds that of OE parts.

However, the poor friction coefficient of plastic material versus steel means that there will always be a potential weakness. With this in mind, MOOG has permanently substituted the plastic outer tube technology with a stronger metal solution.

With this metal technology, MOOG has managed to exceed the pull out value of its OE and competitor equivalents, making MOOG control arms better equipped to deal with unforeseen impacts.

Browse more Technical Content and jump start your technical knowledge with Garage Gurus.

The content contained in this article is for entertainment and informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.