Sway Bar Link Installation Tip

A key part of a car’s suspension system, the sway bar link is susceptible to damage due to overtightening. Read on to learn an important tip for installing MOOG® bolt style sway bar links.

Advice for Avoiding Overtightening

When installing MOOG bolt style sway bar links (also called barrel lock nut), it is important to avoid overtightening the bolt. MOOG bolt style sway bar links feature a self-locking barrel nut on the end of a polyurethane bushing that doesn’t compress like a standard bushing when it is tightened.

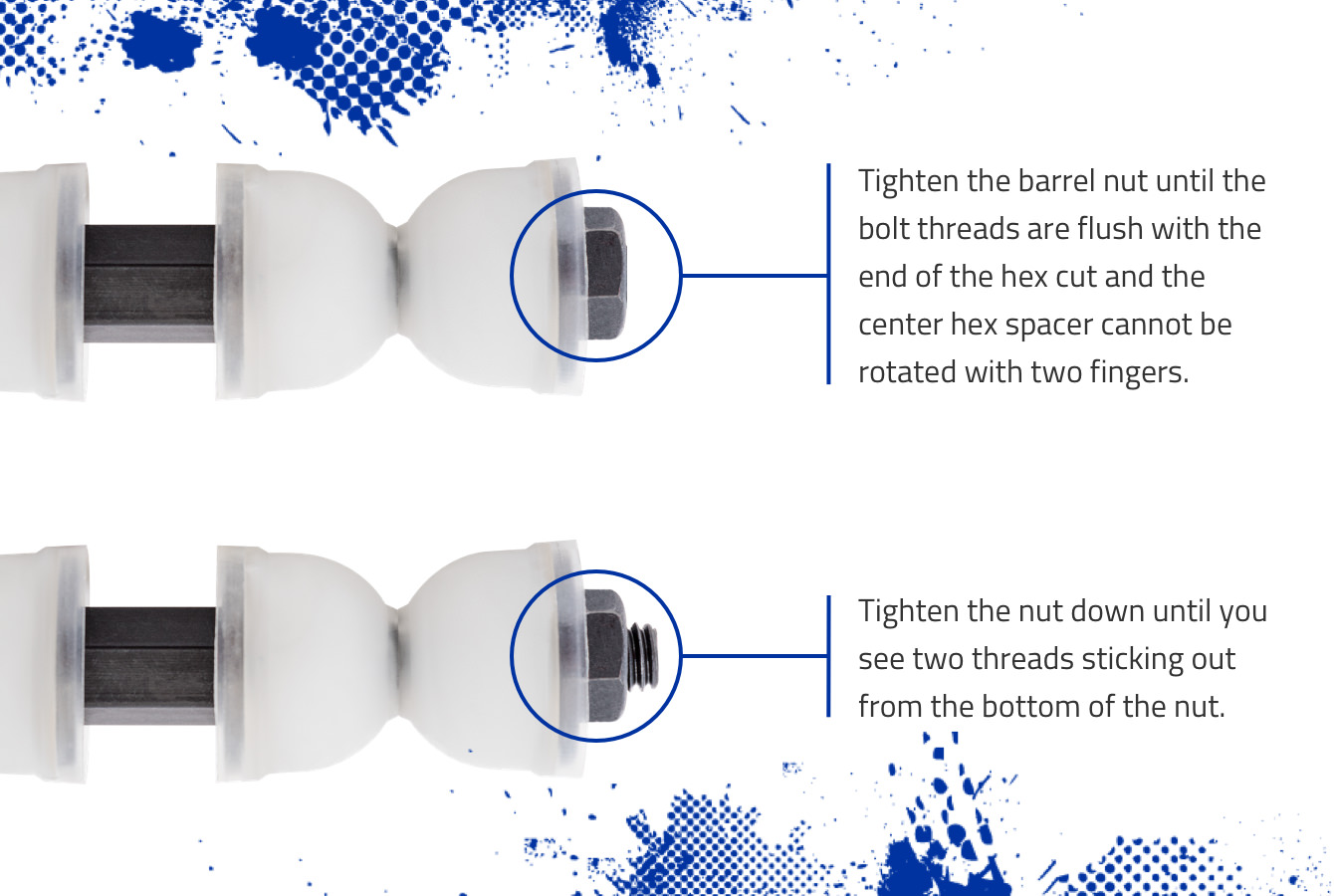

During installation, make sure that you don't overtighten the bolt or you could put excess stress on the stud that could cause it to break. While it generally takes about 14-pounds o pressure to tighten the nut down, there is an easy way to ensure you don't overtighten the bolt that doesn't require the use of a torque wrench.

What Are the Advantages of MOOG Bolt Style Sway Bar Links?

Easier to install than traditional sway bar link kits, the MOOG Problem Solver® bolt style sway bar link features patented molded bushings that center and hold the coated washers in place, making them easier to install. Instead of a standard nut, MOOG sway bar link kits use a 1"-barrel lock nut that can easily be threaded on, even if the bolt end is flush with the washer. This saves time during installation.

Learn more about premium steering and suspension parts, find your car part, or find where to buy your auto part today.

The content in this article is for informational purposes only. You should consult with a certified technician or mechanic if you have questions relating to any of the topics covered herein. Tenneco will not be liable for any loss or damage caused by your reliance on any content.