The Problem

Many times, universal joint part numbers cannot be easily identified, especially by application. Using the online catalog database, MOOG® makes it easy to correctly determine a replacement MOOG universal joint part number. Here’s what you need to get started:

- Old universal joint that needs replacing

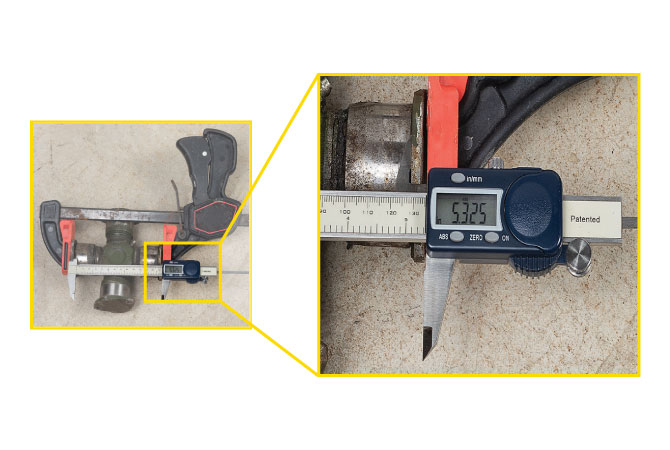

- Calipers for measuring

- C-clamp or vise

- Internet access

Identification Procedure

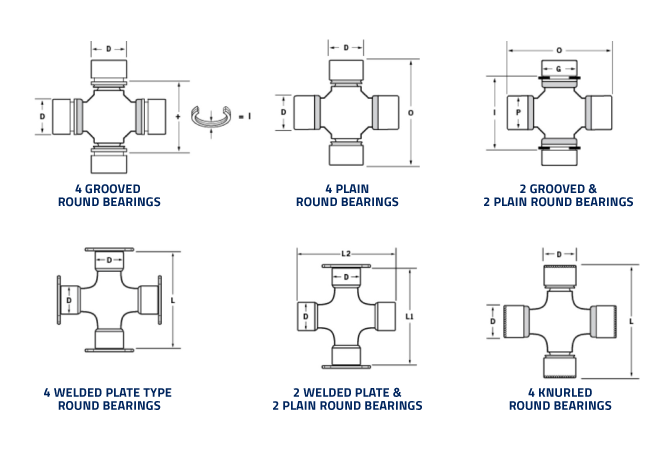

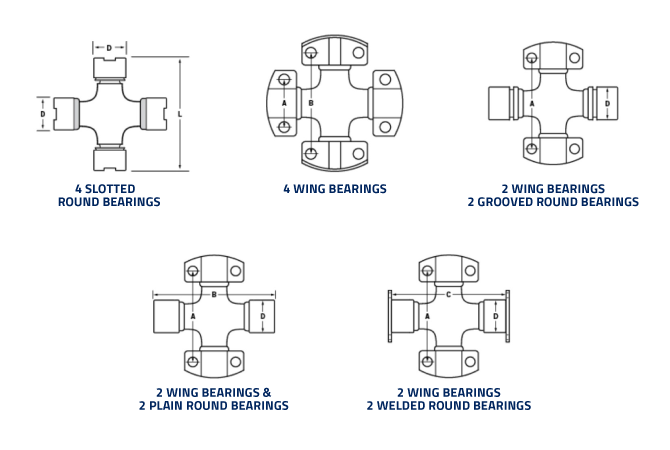

Step 1: Find the Correct Style of U-Joint

Step 2: Measure Bearing Caps

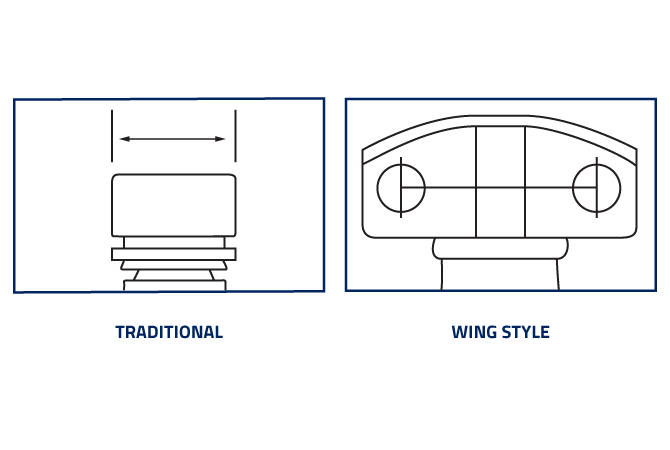

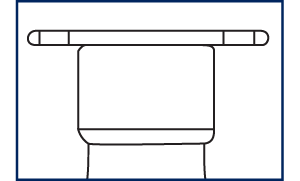

Traditional cap styles pressed in yoke: Measure diameter of bearing cap

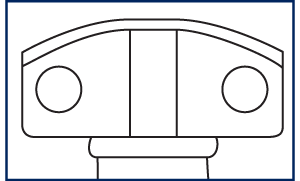

Wing bearing caps: Measure hole spacing (center-to-center)

Tip: Measure two adjacent caps even if they’re the same style in case they are different sizes.

Step 3: Measure U-joint assembly. Refer to chart in Step 1 for correct style.

Plain round bearings, knurled round bearings and slotted round bearings: Remove grease boots, ensure caps are fully seated by applying light pressure using a C-clamp or vise at both ends of cups (tight enough that the u-joint cross body can be turned by hand), and measure the overall length from cap-to-cap.

Grooved round bearings: Remove grease boots and ensure caps are fully seated by applying tight pressure using a C-clamp or a vise at both ends of cups (tight enough that the U-joint cross body can be turned by hand). Measure the inside edge of the lock ring groove on one bearing across the joint to the same point on the opposite bearings. Measure the thickness of the locks rings and add their thickness to the first measurement.

Welded plate bearings: Remove grease boots and ensure caps are fully seated by applying light pressure using a C-clamp or a vise at both ends of cups (tight enough that the u-joint cross body can be turned by hand). Measure the distance between the opposite plates. Don’t include the plate thickness in the measurement.

Winged bearings: Measure the distance between the holes directly across from each other and the pilot diameter. Make sure to take note of the style of the wings as there are many variations.

On all U-joint styles, the measured dimension should be slightly less than the dimensions you’ll use to look up the part number. Make sure to take note of the type and location of grease fittings and to write down your measurements.

Step 4: Visit Online Catalog Database

From there, you can use the measurements to identify which part number(s) will fit your application.

For parts lookup, go online or call the Tech Line: 1-800-325-8886

Learn more about premium steering and suspension parts, find your car part, or find where to buy your auto part today.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.